Location

The Bahía de Bizkaia Electricidad S.L. plant is located in the municipality of Zierbena (Bizkaia), in the Autonomous Community of the Basque country (Spain). BBE’s combined-cycle power plant is located on a site covering approximately five hectares on land being developed at Punta Lucero to make way for the expansion of the port of Bilbao.

Bahía de Bizkaia Gas S.L. regasification terminal lies immediately to the north west of the plant with the TEPSA facility lying immediately north east, the substation to the south east, and the road running parallel to the plant to the south.

The sea lies 250 metres north east of the plant. The plant is situated on flat ground at sea level.

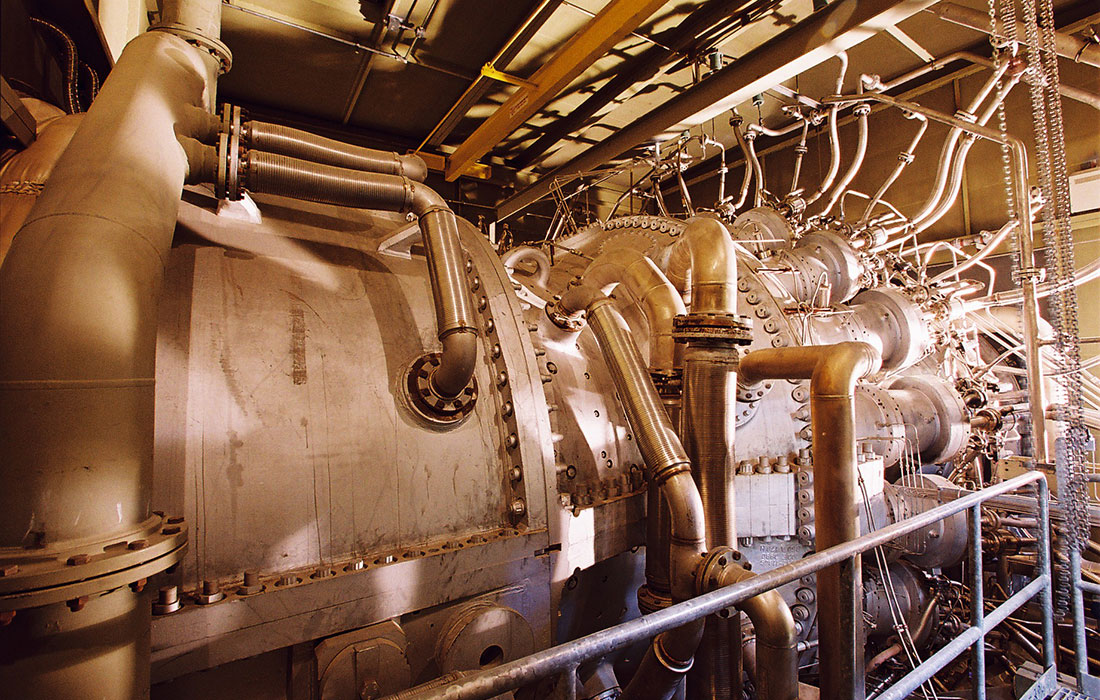

Technology and layout

The plant is based on a “2 x 1” configuration comprising two MS 9001 FA General Electric gas turbines, two natural-circulation heat recovery steam generators with three pressure levels (supplied by Babcock Wilcox Española), and a three-stage General Electric steam turbine with reheating.

Both the gas and the steam turbines operate their respective generators in line with the multi-axis (2 x 1) concept. The gas turbines are high-performance industrial units using state-of-the-art technology to keep NOx and CO emissions at a minimum.

The gas turbines are positioned on a bed at ground level and the steam turbine on a raised platform so that the single-pass condenser can be positioned below the stage exhaust underneath the turbine. The condenser is cooled by an open circuit containing seawater.

All the turbines are located inside the turbine building. The heat recovery steam generators are housed in the boiler building.

The main and auxiliary transformers are located outdoors between the turbine building and the REE substation.

The gas turbines use natural gas preheated by water extracted from the heat recovery steam generators, the aim being to increase the efficiency of the combined cycle.

The design of the combined cycle plant was based on the following criteria:

Flexibility:

The plant can operate with both base and partial loads with excellent results.Shorter start-up times:

The 100% bypasses mean the gas turbine and the heat recovery steam generator can be started separately without having to start the steam turbine, cutting the start-up time in the process.High availability:

The equipment is tried and tested and this, in conjunction with the appropriate redundancies, guarantees exceptionally high availability.High efficiency:

The plant's high efficiency levels are based on:- Optimisation of the steam cycle based on high live steam and hot reheat steam temperatures in addition to high condenser vacuum values.

- Maximum use of gas-turbine exhaust gases with a reduced number of pinch points in the boiler and low smokestack-gas temperatures.

- Preheating of the gas consumed in the turbine.

- Variable geometry stator vanes in the gas turbine compressor.

Low pollution levels:

The use of technologies such as the Dry Low NOx Combustor, and the application of the combined-cycle concept, which reduces CO2 emissions, ensure that the plant emits low levels of pollution.

Power and outputs

In nominal operating conditions the plant produces a net power output at the high voltage bushings of the main transformers of 800 MW, with a specific consumption of 6,355 kJ/kWh.

This power output is broken down as follows.

- Gas turbine 1: 256,6 MW

- Gas turbine 2: 257,4 MW

- Steam turbine: 271,3 MW

- Auxiliary consumption: 12.213 kW

Fuel

The only fuel used at the plant is natural gas although diesel oil may be used at some point in the future as the turbines are equipped to run on it. The minimum required pressure is 35 bar.

BBE's regasification terminal will supply the gas needed to run the plant and in the conditions required by the gas turbines.

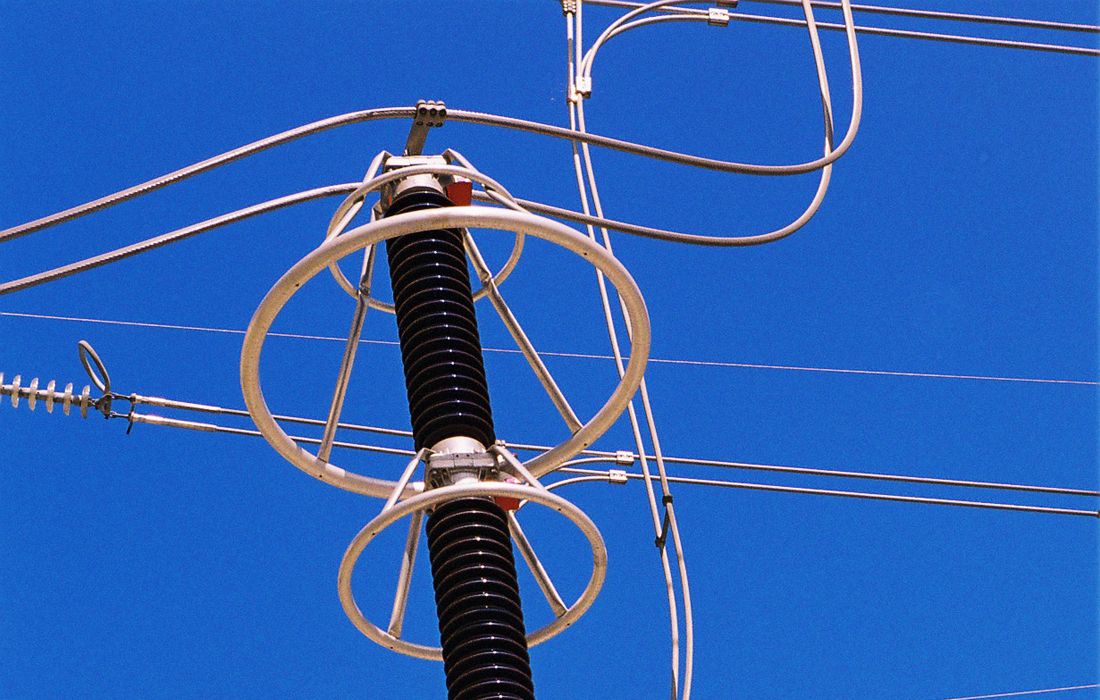

Power supply connection

The BBE plant will be connected to the Spanish national grid (REE) by a connection to a new 400 kV substation (built by REE).

The supply limit of the BBE plant is set in the autovalves (400kV) of the main transformers.

Main cooling circuit

The condenser and the closed cooling circuit are both cooled by an open circuit containing seawater.

The pump house is located by the sea and is connected to the plant by underground concrete pipes. After passing through the condenser the seawater runs through an underwater pipe and is discharged back into the sea at a distance of 50 m from the coast and at depth of around 20 m. The pipe running through the site is connected to the BBG plant, which uses part of the seawater in the liquid-gas vaporization process.

Key Characteristics:

- Length of cooling circuit: 840 m.

- Internal diameter of pipes: 2,5-3 m.

- Length of emissary: 50 m.

Pump House:

- Seawater flow: 14,4 m3/s.

- Dimensions: 31,3×17,2×15(h)m.

- Depth: -7,5 m.

Environmental impact

The plant observes the maximum permissible liquid, gas and noise emission levels.

Low NOx burners are installed in the gas turbines to keep NOx emissions below 50 mg/Nm3. In addition, the smokestack (supplied by KARMAN) stands 125 m high, thus enabling the dispersion of gaseous pollutants.

Design conditions

Environmental conditions:

- Ambient temperature (design): 15°C

- Ambient temperature range: -6,6°C-41,7°C

- Relative humidity (design): 73%

- Relative humidity range: 56% – 85%

- Atmospheric pressure (design): 1015 mbar

- Height above sea level: Sea level

- Location: On the coast

- Maximum wind speed: 148 km/h

- Snow load: Not applicable

Main cooling circuit:

- Coolant: Seawater

- Temperature of seawater: 19°C

- Temperature jump in condenser: 8°C

Fuel:

- Fuel used: Natural gas

- Backup fuel: Possibility of switching to diesel oil

- Minimum pressure required: 35 bar

- Preheating of gas: Included